- Browse Categories

- Continuous waste tire pyrolysis equipment

- Continuous waste rubber pyrolysis equipment

- Continuous waste plastic pyrolysis equipment

- batch type waste tyre/plastic pyrolysis machine

- Waste engine oil refining equipment

- Waste Gear Oil Recycling Machine

- Used Fuel Oil Purification Machine

- Pyrolysis oil refining machine

- Garbage plastic to oil

- Auxiliary equipment

- Apron feeder

- Belt conveyor

- Screw conveyor

- Bucket elevator

- Scraper conveyor

- Heavy oil bunner

- Subscribe

-

Get email updates on new products

- Contact Us

-

Mob/Whatsapp: +0086-13373761810

Tel: +0086-13373761810

Fax: +86-371-55013221

Skype: Xintong1109

E-mail: emma@odifei.com.cn Contact Now

- Hot Products

- News

-

Oil sludge

1.Sludge concept Oily sludge is one of the main pollutants in the petrochemical industry where the crude oil is mixed with the oil or other medium, and the oil can not be recovered directly and may cause pollution. 2.Brief introduction of sludge Petrochemical enterprises sewage treatment system to produce sludge mainly from the grease trap of the sediment, flotation pool scum, the remaining activated sludge, collectively referred to as "three mud." Oily sludge also includes contaminated sludge in steel smelting, sludge repayment of heavy oil in the process of repairing shipyards Oily sludge is usually composed of oil-in-water (o / w), water-in-oil (w / o) and suspended solids consisting of a stable suspension of emulsion system, poor dehydraDelivery to Russia

This is tons waste tyre pyrolysis equipmentCustomer equipment display

Customer equipment display6 tons waste tire pyrolysis plant

6 tons waste tire pyrolysis plant This is 6 tons waste tire pyrolysis plant . We shiped to Kazakhstan by train.customer factory show

This is the customer's spot map. His handling capacity is 10 tons per day, the raw material is waste tire. The finished products are fuel oil, steel wire and carbon black.Customer factory

This is our customer factory. This plant is 10 tons capacity per day.It can pyrolysis waste tire,waste plastic and waste rubber.Safety, environmental protection, pollution-free.Deliver goods

How to choose a suitbale factory to product the waste tyres recycling machine?

How to choose a suitbale factory to product the waste tyres recycling machine? More and more people are optimistic about the project of refining equip...Automatic slagging screw

This is a fully automatic carbon black slag discharge system. Can achieve no pollution, no dust.50 tons heavy fuel oil distillation equipment instillation

50 tons heavy fuel oil distillation equipment instillation

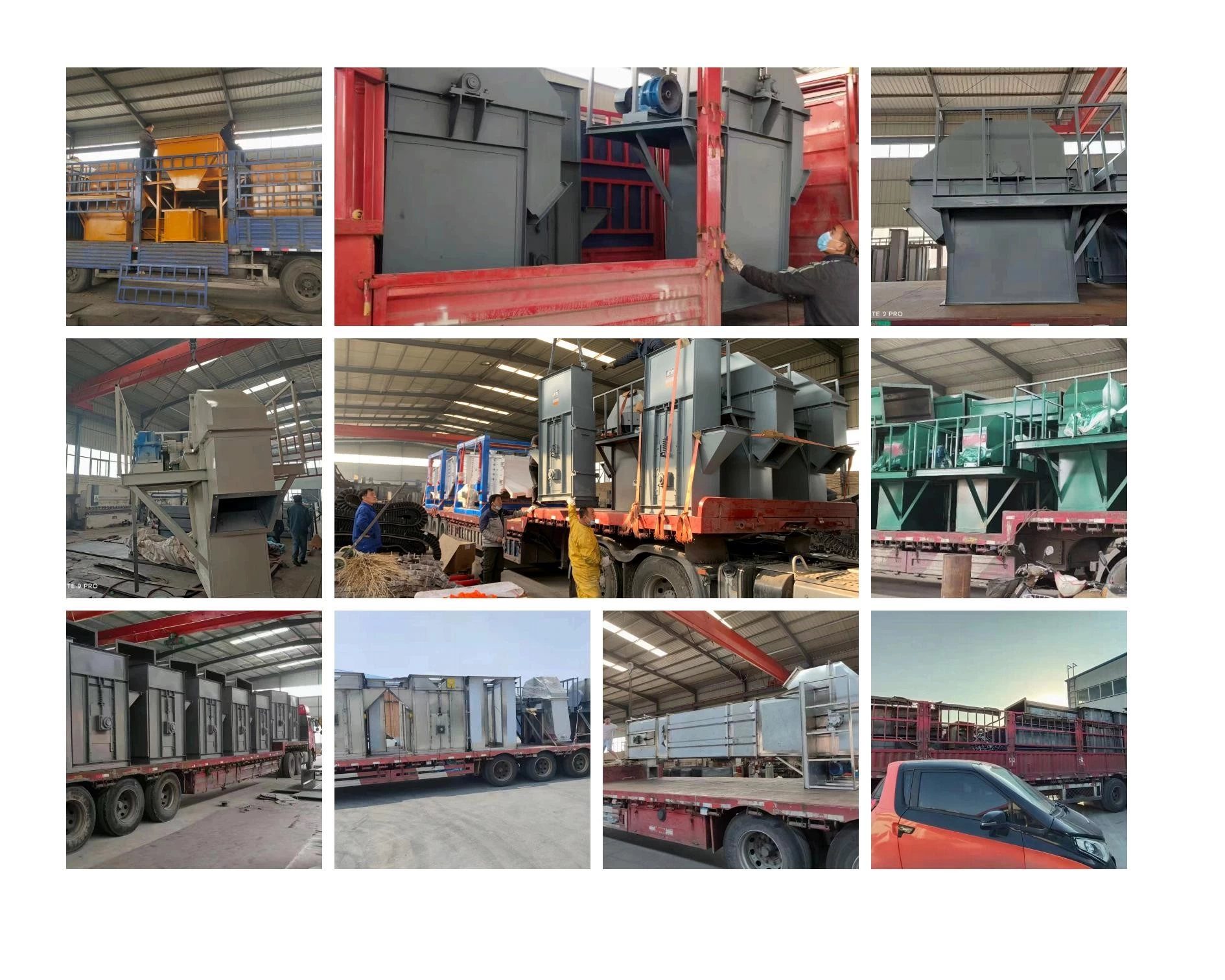

TD/TH/NE Vertical Chain Belt Bucket Elevator for Cement

- Applicable Industries:Material handling

- Material:Carbon steel

- Material Feature:Heat Resistant

- Structure:Conveyor System

- Voltage:220v or as your local power

- Power:As the model you choose

- Dimension(L*W*H):Customized Size

- Width or Diameter:Custom

- Machinery Test Report:Provided

- Warranty of core components:1 Year

- Weight (KG):3000 kg

- Color:As requirement

TD/TH/NE Vertical Chain Belt Bucket Elevator for Cement

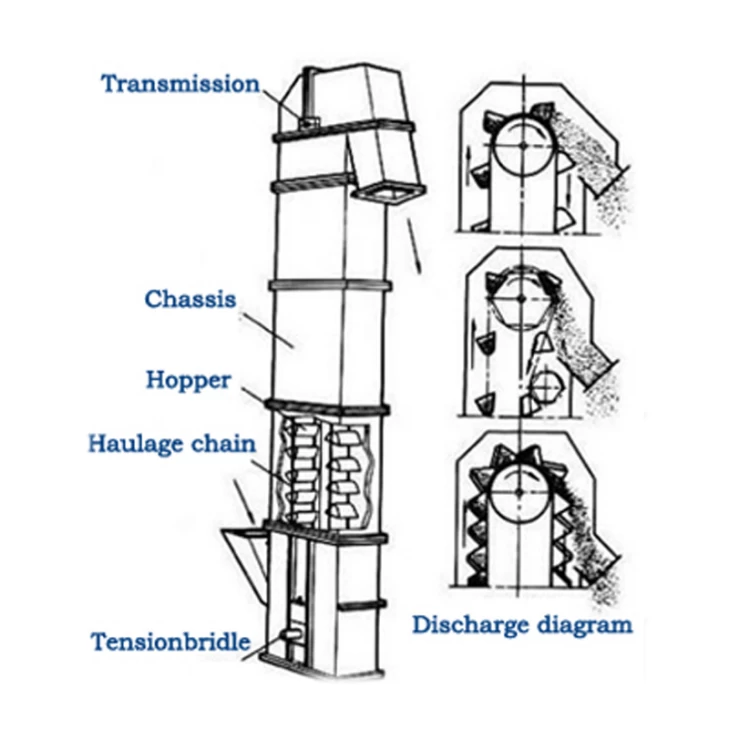

Introduction of the bucket elevator

TD/TH/NE Vertical Chain Belt Bucket Elevator is a heavy-duty machine. Bucket elevators are Very stable running, Small footprint, High conveying capacity, Many different line versions available, and Multiple drop-off points are possible. Bucket conveyor elevators convey products like resistant materials, chemical granules, sand, pellets, powders, and many other industrial applications for free-flowing, dry material.

Structural features

Technical Parameters

|

model |

TDl60 |

TD250 |

TD315 |

TD400 |

||||||||||||||

|

Hopper form |

Q |

H |

Zd |

Sd |

Q |

H |

Zd |

Sd |

Q |

H |

Zd |

Sd |

Q |

H |

Zd |

Sd |

||

|

delivery volume (m3/h) |

5.4 |

9.6 |

9.6 |

16 |

12 |

22 |

23 |

35 |

17 |

30 |

25 |

40 |

24 |

46 |

41 |

66 |

||

|

Bucket width(mm) |

160 |

250 |

315 |

400 |

||||||||||||||

|

Bucket capacity(L) |

O.5 |

O.9 |

1.2 |

1-9 |

1.3 |

2.2 |

3.O |

4.6 |

2 |

3.6 |

3.8 |

5.8 |

3.1 |

5.6 |

5.9 |

9.4 |

||

|

Bucket distance(mm) |

280 |

350 |

360 |

450 |

400 |

500 |

480 |

560 |

||||||||||

|

bandwidth(mm) |

200 |

300 |

400 |

500 |

||||||||||||||

|

bucket speed(m/s) |

1.4 |

1.6 |

1.6 |

1.8 |

||||||||||||||

|

Largest piece of material(mm) |

25 |

35 |

45 |

55 |

||||||||||||||

|

model |

TD500 |

TD630 |

D160 |

D250 |

D350 |

D450 |

||||||||||||

|

Hopper form |

Q |

H |

Zd |

Sd |

H |

Zd |

Sd |

Q |

S |

Q |

S |

Q |

S |

Q |

S |

|||

|

delivery volume (m3/h) |

38 |

70 |

58 |

92 |

85 |

89 |

142 |

4.7 |

8 |

18 |

22 |

25 |

42 |

50 |

72 |

|||

|

Bucket width(mm) |

500 |

630 |

160 |

250 |

350 |

450 |

||||||||||||

|

Bucket capacity(L) |

4.8 |

9 |

9.3 |

15 |

14 |

14.623.5 |

23.5 |

0.65|1.1 |

2.6 |

3.2 |

7 |

9.8 |

14.5 |

18 |

||||

|

Bucket distance(mm) |

500 |

630 |

710 |

300 |

400 |

500 |

640 |

|||||||||||

|

bandwidth(mm) |

600 |

700 |

200 |

300 |

400 |

500 |

||||||||||||

|

bucket speed(m/s) |

1.8 |

2 |

1 |

1.25 |

1.25 |

1.25 |

||||||||||||

|

Largest piece of material(mm) |

60 |

70 |

25 |

35 |

45 |

55 |

||||||||||||

Working principle of the Bucket Elevator for Cement

The hopper scoops up the material from the storage below, lifts to the top with the conveyor belt or chain, bypasses the top wheel and turns down, and the bucket elevator dumps the material into the receiving trough. The transmission belt of the bucket elevator with transmission is generally a rubber belt, which is installed on the lower or upper driving roller and the upper and lower redirecting roller.

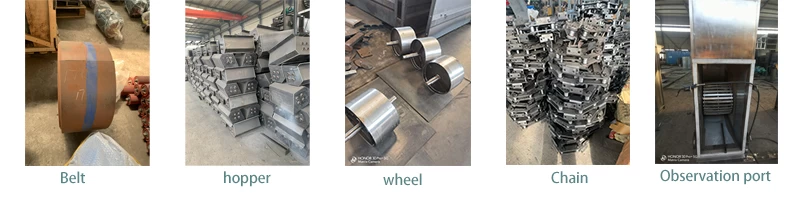

Product Parts

Applicable raw materials

Belt Bucket Elevator is mainly used in grain processing production line (such as rice mill production line, millet production line, wheat flour production line, etc) for the vertical continuous conveying of powdery materials or granular materials, such as grains (paddy rice, rice, wheat, corn, soybeans, sesame, sorghum, etc).

Product advantages of the bucket elevator:

1.Easy maintenance, long service life.

2.The chassis plate thickening, good rigidity.

3.The conveying material temperature up to 250 ℃. Section

4.In the case with a single channel and dual channel two forms.

5.Hoisting height stable and reliable operation, low noise, easy maintenance.

6.Improve models improve throughput is 30% greater than normal models.

7. Hoist chain using low alloy steel forging, and after carburizing and quenching processes, and have high tensile strength and wear resistance.