-

1. What is a pyrolysis machine?

-

What is a pyrolysis machine?

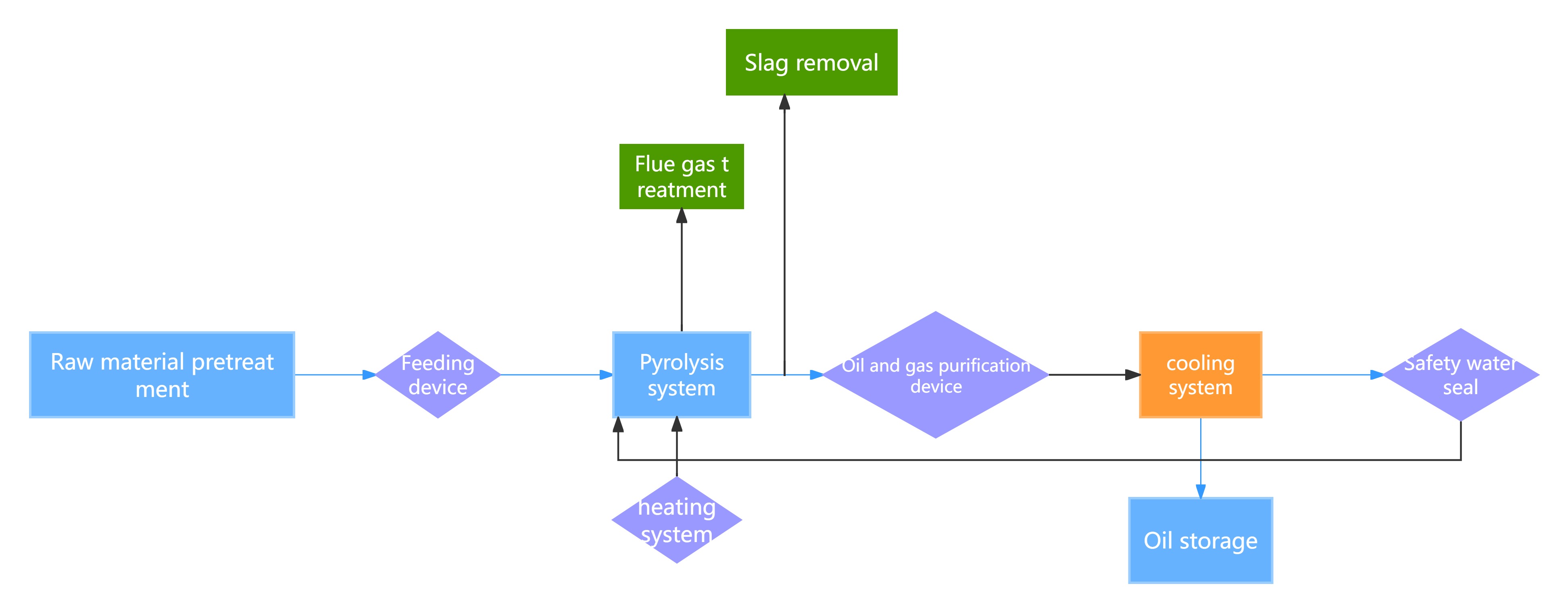

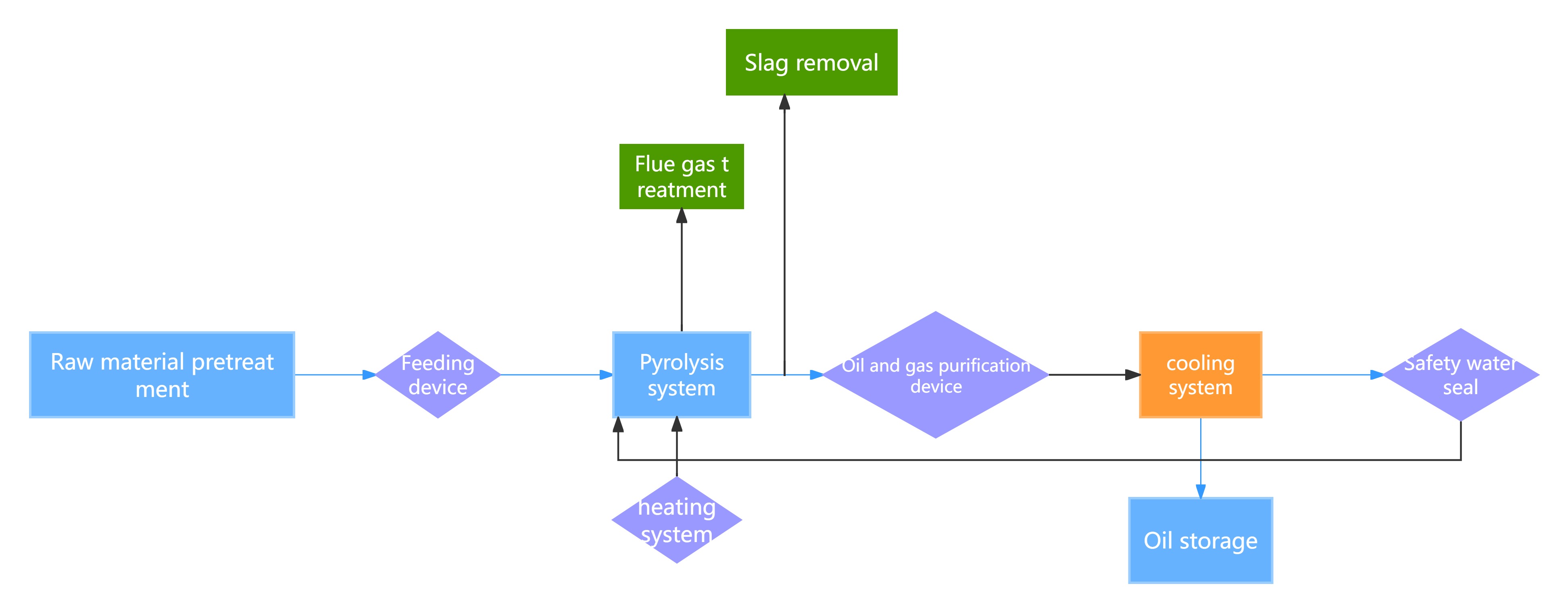

A pyrolysis machine is the machine which can convert the waste tyre,plastic,oil sludge,aluminum plastic into the fuel oil,carbon black,steel wire,aluminum or other metal.

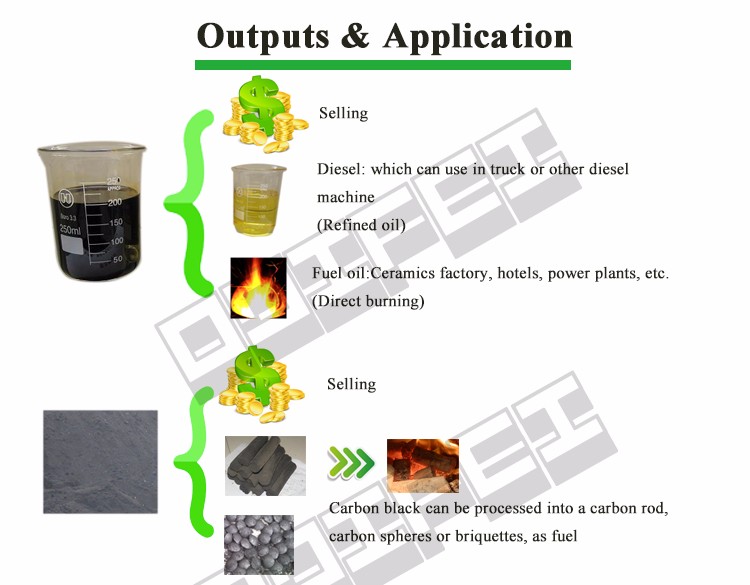

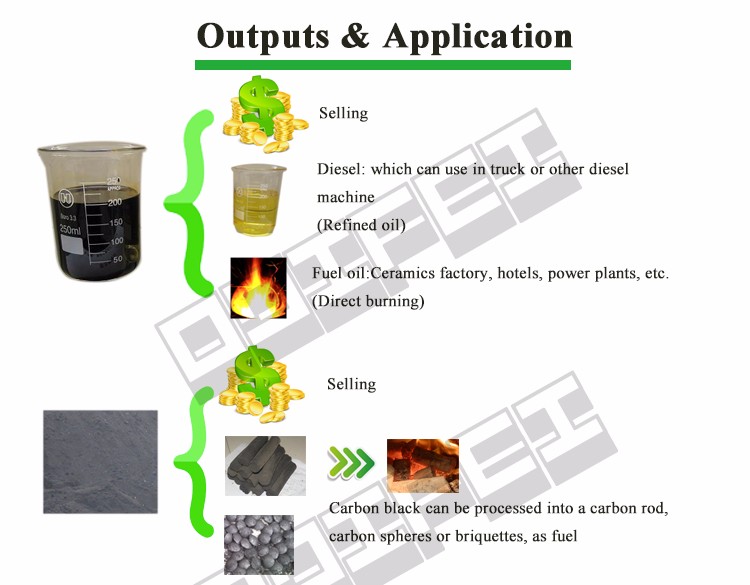

The final output products usage

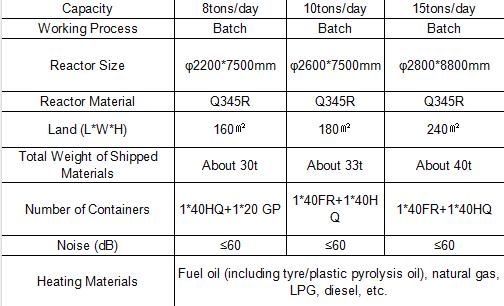

The model of the pyrolysis machine

Shipping picture of the machine

-

2. What is the difference between semi-continuous pyrolysis equipment and fully continuous pyrolysis equipment?

-

The main difference between semi-continuous pyrolysis equipment and fully continuous pyrolysis equipment is that semi-automatic refining equipment needs to be cooled down and shut down to discharge slag before it can be fed twice; while fully automatic pyrolysis equipment does not need to be cooled down and shut down, and can feed and discharge slag at the same time. ;

-

3. What models are available for semi-continuous cracking equipment? How much output can be processed in a day?

-

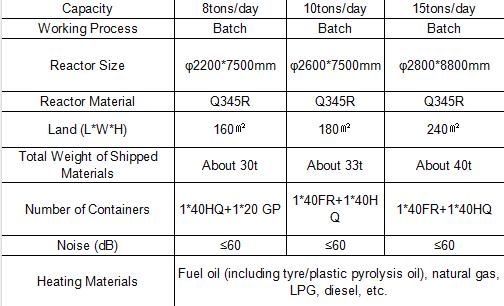

Semi-continuous pyrolysis equipment is generally divided according to processing capacity, and the common ones are 10 tons, 15 tons, and 20 tons;

-

4. What materials can be cracked by semi-continuous refining equipment?

-

Rubber powder, rubber blocks, broken plastics and other crushed small granular raw materials, sludge and oil residues, rubber, electronic waste, etc. The materials must not contain solid impurities that cannot be cracked, such as bricks, metals, stones, etc.;

-

5. What is the uses of the carbon black?

-

carbon black is the main product recycled by pyrolysis technology,the amount of recycled carbon black is 35%-42%,carbon black is used as raw material or main ingredient in many industries and chemical struture of carbon black strengthens,lengthens the endurance,and improves the coloring features of the materials.

Many costomers will use the carbon black pellet machine to make the carbon black powder into the ball.

More information about the carbon black pellet machine,you can contact with us :+86-13303710540.

-

6. What is the installation direction of the scraper conveyor scraper?

-

The scraper is a very important part of the scraper conveyor. The direction of the scraper must not be installed wrongly. The bolts connecting the scraper in the horizontal direction must face the running direction. The head of the bolt connecting the scraper in the vertical direction must face the middle plate.

-

7. What are the structural components of the scraper conveyor?

-

The scraper conveyor can be used for horizontal transportation and can also be used for inclined transportation. When transporting upwards along the slope, the inclination angle of the coal seam shall not exceed 25°, and when transporting downward, the inclination angle shall not exceed 20°. When the inclination angle of the coal seam is large, an anti-skid device shall be installed. then you know

The main structure and components of various types of scraper conveyors are basically the same, and it consists of three parts: the nose, the middle and the tail.

In addition, there are auxiliary parts such as a hydraulic jack device for the push conveyor and a chain tensioner for chain tightening. The machine head is composed of a machine head frame, an electric motor, a hydraulic coupling, a reducer and a sprocket. The middle part is composed of transition grooves, middle grooves, chains and scrapers. The tail of the machine is the device for the return of the scraper chain. The tail of the heavy-duty scraper conveyor is the same as the head, and it is also equipped with a power transmission device, which is called the upper head and the lower head from the installation position.

-

8. What's the usage of the Pyrolysis oil? Can it be used in vehicles?

-

(1) The pyrolysis oil is fuel oil and can be used as fuel in some heavy industry factories, such as glass factory, power plant factory, aluminum factory and so on.

(2) If you want to use the oil in vehicles, you may need the distillation plant. It can distill the pyrolysis oil into diesel.

-

9. What's the difference between continuous pyrolysis plant and intermittent pyrolysis plant?

-

They are different in the following aspects:

For the continuous type, the feeding of raw materials and discharging of slag are both automatic. While for the intermittent type, these two processes are manual.

For the continuous type, the feeding hole is very small, so the pretreating system is needed to cut the raw materials into small piece. While the intermittent type does not need this device.

The continuous plant can operate for some time without stop. While for the intermittent plant, the reactor must be cooled before the second batch.

-

10. Can tire and plastic be mixed to be processed?

-

Generally, we don't recommend you to mix them. Tire and plastic need different temperature and time to be processed. If you put them together, much fuel will be wasted. Besides, the quality and rate of final oil will also change.

-

11. How you can clean the emission to meet environmental standard?

-

3 layers of dedusting system-alkali liquor wasing+ceramic filtering+alkali liquor sprayers. Extra gas from reactor will be recycled into furnace for heating, it will be cleaned by specific device before to be burned of cause. Ash and odor are also well prevented as the pyrolysis system is totally sealed, sepcially for continuous running plants.

-

12. How long does will take you to delivery ?

-

A. In stock, within 15 days after received the advanced payment;

B. Out of stock, within 25 days after received the advanced payment.

-

13. How about your after-service ?

-

We will provide one year free warranty for our machine, and after machine delivery, we have the engineers which can be sent to your site for machine installation, commissioning and training your workers. You also can feel free to contact us, when you have any questions about our machine.

-

14. How does your factory do regarding quality control ?

-

Quality is priority, since establishment, we keep strictly requirements about the quality with using X-Ray to test every section of the products, so we gain high praise from our customers ,all product have to pass strict inspection before they were sent out.

-

15. Where is your factory ?

-

Our factory is locate in the industrial area, which only takes about one and half hour from Zhengzhou national airport to our factory. And we have the office very near to the airport which can pick you up directly from the airport to our office or factory. Welcome your visiting!!

-

16. Are you manufacturer or trade compnay ?

-

We are the manufacturer, which have more than 15 years experience specialized in all kinds of waste recycling machinery.

-

17. Why choose us?

-

Engineers available to service machinery overseas.

We can make the model according your requirements.

We could help customer choose the right model and also provide customization.

-

18. Is your Transfer Cart customized?

-

Yes, we can product it according to your needs.