Can scraps from electronics factories be refined into oil?

Can scraps from electronics factories be refined into oil?

Can waste materials from electronic factories be refined into oil? This question has been raised after a recent report revealed the staggering amount of electronic waste being generated around the world, and the need for sustainable disposal methods.

Electronic waste or e-waste is a term used to describe discarded electronic devices or components. According to the United Nations University (UNU), the world generated 53.6 million metric tons of e-waste in 2019, which is equivalent to the weight of 350 cruise ships.

While some of this waste is recycled, most of it ends up in landfills, causing environmental and health hazards due to hazardous materials such as lead and mercury. Therefore, finding sustainable ways to dispose of e-waste is increasingly gaining importance.

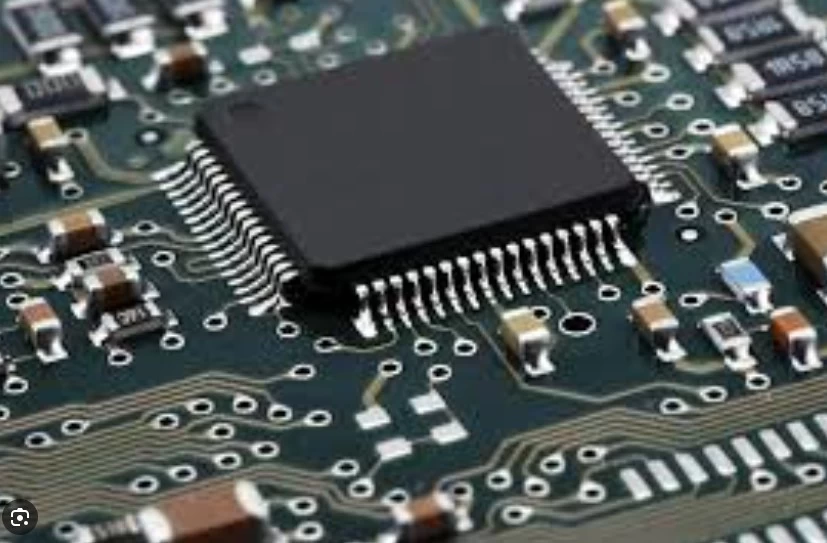

Our ODF system E-waste recycling equipment is refining e-waste into fuel oil. such as printed circuit boards.

The refining process of electronic waste cracking and refining equipment can be divided into the following steps: charging, cracking reaction, separation and refining.

The first is loading. E-waste can be loaded manually or using an automatic feeding machine;

Next comes the cleavage reaction. In the pyrolysis reaction, e-waste is heated to high temperatures and decomposed in an oxygen-deficient or low-oxygen environment. During this process, the polymer chains in the electronic waste are broken, producing a series of hydrocarbons.

The gaseous state of these hydrocarbons can then be further cooled and converted into petroleum products such as gasoline, diesel and lubricants.

The refining process of e-waste refining equipment is a complex process that requires precision equipment and strict operational control. However, it is a viable technology that can effectively process e-waste and convert it into useful petroleum products. Through e-waste cracking and refining equipment, we can achieve the goal of resource utilization of e-waste, reduce the demand for traditional petroleum resources, and reduce environmental pollution.