- Browse Categories

- Continuous waste tire pyrolysis equipment

- Continuous waste rubber pyrolysis equipment

- Continuous waste plastic pyrolysis equipment

- batch type waste tyre/plastic pyrolysis machine

- Waste engine oil refining equipment

- Waste Gear Oil Recycling Machine

- Used Fuel Oil Purification Machine

- Pyrolysis oil refining machine

- Garbage plastic to oil

- Auxiliary equipment

- Apron feeder

- Belt conveyor

- Screw conveyor

- Bucket elevator

- Scraper conveyor

- Heavy oil bunner

- Subscribe

-

Get email updates on new products

- Contact Us

- Contact Now

- Hot Products

- News

-

Oil sludge

1.Sludge concept Oily sludge is one of the main pollutants in the petrochemical industry where the crude oil is mixed with the oil or other medium, and the oil can not be recovered directly and may cause pollution. 2.Brief introduction of sludge Petrochemical enterprises sewage treatment system to produce sludge mainly from the grease trap of the sediment, flotation pool scum, the remaining activated sludge, collectively referred to as "three mud." Oily sludge also includes contaminated sludge in steel smelting, sludge repayment of heavy oil in the process of repairing shipyards Oily sludge is usually composed of oil-in-water (o / w), water-in-oil (w / o) and suspended solids consisting of a stable suspension of emulsion system, poor dehydraDelivery to Russia

This is tons waste tyre pyrolysis equipmentCustomer equipment display

Customer equipment display6 tons waste tire pyrolysis plant

6 tons waste tire pyrolysis plant This is 6 tons waste tire pyrolysis plant . We shiped to Kazakhstan by train.Deliver goods

Customer factory

This is our customer factory. This plant is 10 tons capacity per day.It can pyrolysis waste tire,waste plastic and waste rubber.Safety, environmental protection, pollution-free.customer factory show

This is the customer's spot map. His handling capacity is 10 tons per day, the raw material is waste tire. The finished products are fuel oil, steel wire and carbon black.Automatic slagging screw

This is a fully automatic carbon black slag discharge system. Can achieve no pollution, no dust.How to choose a suitbale factory to product the waste tyres recycling machine?

How to choose a suitbale factory to product the waste tyres recycling machine? More and more people are optimistic about the project of refining equip...What Is The Pyrolysis Machine?

What Is The Pyrolysis Machine? The Pyrolysis Machine is a waste material recycling equipment designed to convert waste tires, plastics, sludge, alumin...

Climbing belt conveyor

- Belt Width: Up to 2.4m

- Belt Length: Up to 10,000m

- Handling Capacity: Up to 10,000 m³/h

- Belt Speed: Up to 6.0m/s

- Max Incline:Maximum 25º

Climbing belt conveyor

Introduction of Climbing belt conveyor

A Climbing Belt Conveyor is a specialized conveyor system designed to transport materials at an incline or decline. It is widely used in industries such as manufacturing, mining, agriculture, logistics, and packaging. This type of conveyor enhances efficiency by moving bulk or packaged goods across different elevation levels smoothly and securely.

Applicable material range of Climbing belt conveyor

Key Features of the Climbing belt conveyor

-

Inclined or Declined Transport

-

Allows smooth movement of materials at various angles.

-

Adjustable incline angles to meet different application needs.

-

-

High-Performance Belt Material

-

Available in rubber, PVC, or PU for durability and adaptability.

-

Anti-slip properties for secure material transport.

-

-

Modular Design & Customization

-

Can be customized with side guards, cleats, and rollers.

-

Available in different belt widths and conveyor lengths.

-

-

Energy Efficient & Cost-Effective

-

Reduces manual handling and increases automation.

-

Low maintenance requirements.

-

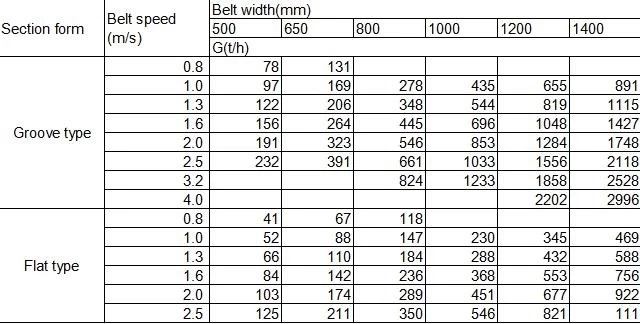

Technical Parameters of the belt conveyor ( General purpose belt conveyor)

Note: The conveying capacity is calculated under the conditions of material bulk density lt/m3, conveying inclination 0°~7°, and material accumulation angle 30°.

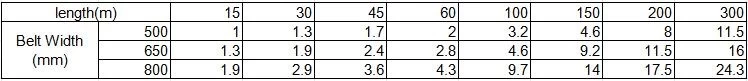

Note:The above power estimation conditions are calculated under ideal conditions of normal humidity, horizontal belt speed of 1m/s, material capacity of 1t/m3, and material stacking angle of 30°. In general, the power used should be about 30% more than the power in the table. If other devices are added, the power should be increased and calculated more heavily.

Application of the belt conveyor