- Browse Categories

- Continuous waste tire pyrolysis equipment

- Continuous waste rubber pyrolysis equipment

- Continuous waste plastic pyrolysis equipment

- batch type waste tyre/plastic pyrolysis machine

- rubber pyrolysis oil

- Waste engine oil refining equipment

- Waste Gear Oil Recycling Machine

- Used Fuel Oil Purification Machine

- Pyrolysis oil refining machine

- Garbage plastic to oil

- Auxiliary equipment

- Heavy oil bunner

- Subscribe

-

Get email updates on new products

- Contact Us

- Contact Now

- Hot Products

- News

-

Oil sludge

1.Sludge concept Oily sludge is one of the main pollutants in the petrochemical industry where the crude oil is mixed with the oil or other medium, and the oil can not be recovered directly and may cause pollution. 2.Brief introduction of sludge Petrochemical enterprises sewage treatment system to produce sludge mainly from the grease trap of the sediment, flotation pool scum, the remaining activated sludge, collectively referred to as "three mud." Oily sludge also includes contaminated sludge in steel smelting, sludge repayment of heavy oil in the process of repairing shipyards Oily sludge is usually composed of oil-in-water (o / w), water-in-oil (w / o) and suspended solids consisting of a stable suspension of emulsion system, poor dehydraDelivery to Russia

This is tons waste tyre pyrolysis equipmentCustomer equipment display

Customer equipment display6 tons waste tire pyrolysis plant

6 tons waste tire pyrolysis plant This is 6 tons waste tire pyrolysis plant . We shiped to Kazakhstan by train.Deliver goods

Customer factory

This is our customer factory. This plant is 10 tons capacity per day.It can pyrolysis waste tire,waste plastic and waste rubber.Safety, environmental protection, pollution-free.customer factory show

This is the customer's spot map. His handling capacity is 10 tons per day, the raw material is waste tire. The finished products are fuel oil, steel wire and carbon black.Automatic slagging screw

This is a fully automatic carbon black slag discharge system. Can achieve no pollution, no dust.How to choose a suitbale factory to product the waste tyres recycling machine?

How to choose a suitbale factory to product the waste tyres recycling machine? More and more people are optimistic about the project of refining equip...What Is The Pyrolysis Machine?

What Is The Pyrolysis Machine? The Pyrolysis Machine is a waste material recycling equipment designed to convert waste tires, plastics, sludge, alumin...

Batch type pyrolysis machine

- Condition:New

- Type:Other

- Place of Origin:Henan, China (Mainland)

- Brand Name:ODF

- Voltage:Customer Request

- Power(W):55KW

- Dimension(L*W*H):30m*18m*5m

- Weight:60T

- Certification:CE ISO SGS

- Name:Low emission used plastic washing recycling line made in China

- Raw material:Waste Tyre

- Application:Continuous Tyre Pyrolysis Plant

- Function:Make Oil

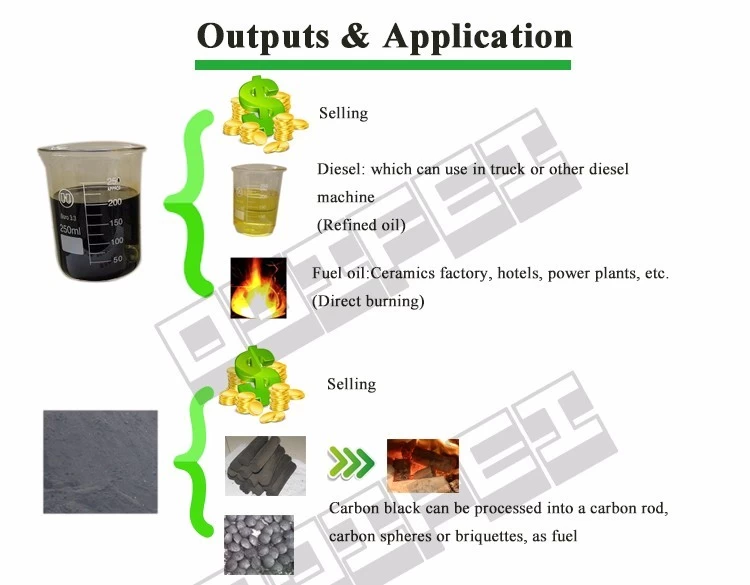

- End product:Fuel Oil Steel Carbon Back

- Color:Customers' Demand

- Item:Oil Equipment

- Suitable Raw Materials:Scrap Steel Tire

- After-sales Service Provided:Engineers available to service machinery overseas

- Warranty:1 Year

Batch type pyrolysis machine

Type pyrolysis machine mainly to convert the waste tyre,plastic,oil suldge into fuel oil,steel wires,carbon black;

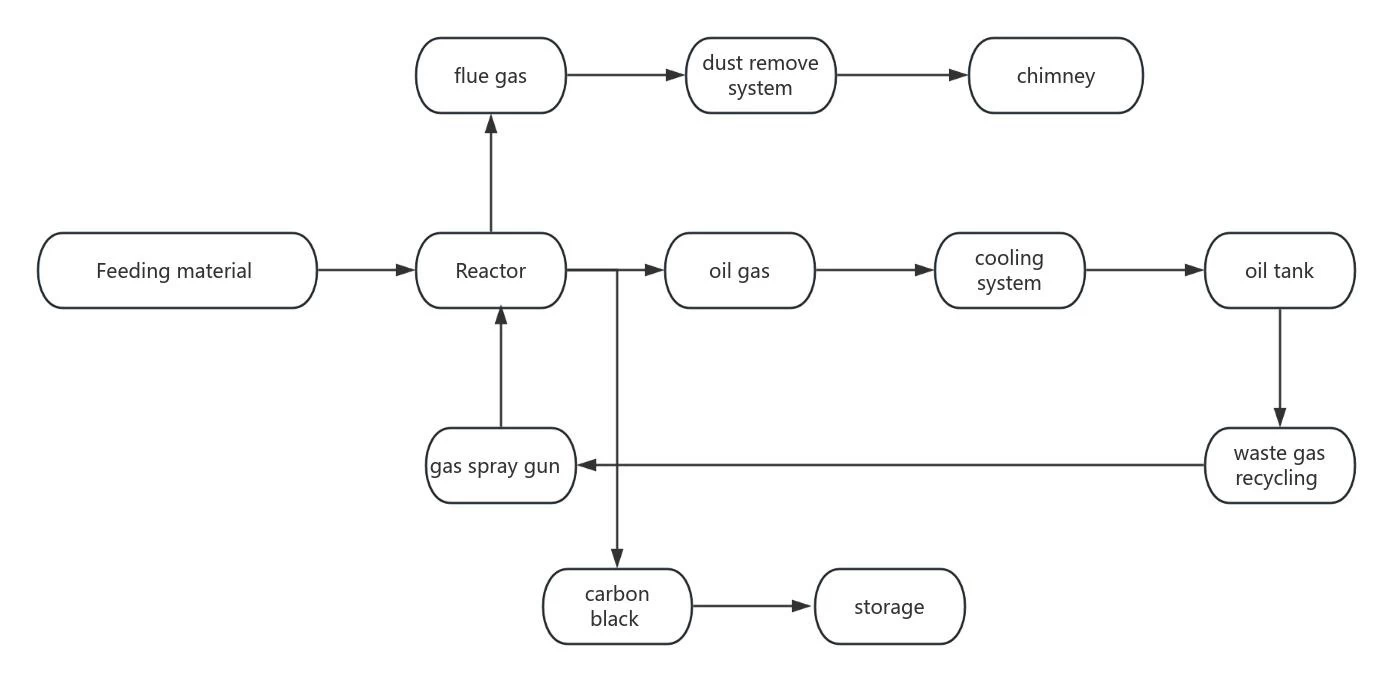

Technological process

Detailed configuration information

|

|

The main reactor is made of standard boiler steel All-inclusive design, good thermal insulation effect |

|

Large-diameter cooling pipes are used. The cooling pipes have double air inlets and a three-way design (to avoid clogging), making them easy to clean and repair. Under normal circumstances, the pipes can be cleaned once every six months of equipment operation; |

|

Non condensable combustible gas recycle system safely recycling waste gas into the combustion chamber to burn to save fuel |

|

Various slag discharge methods are available |

Parameter Table

|

Capacity |

1-20ton per day |

|

Working style |

Batch type |

|

Cooling style |

Water cooling |

|

Raw material |

Waste tyre,plastic,oil sludge.... |

|

Heating style |

Fuel oil,carbon,gas... |

|

Worker |

1-3 people one sets; |

|

Weight of machine |

Depend on the model; |

Final products Use

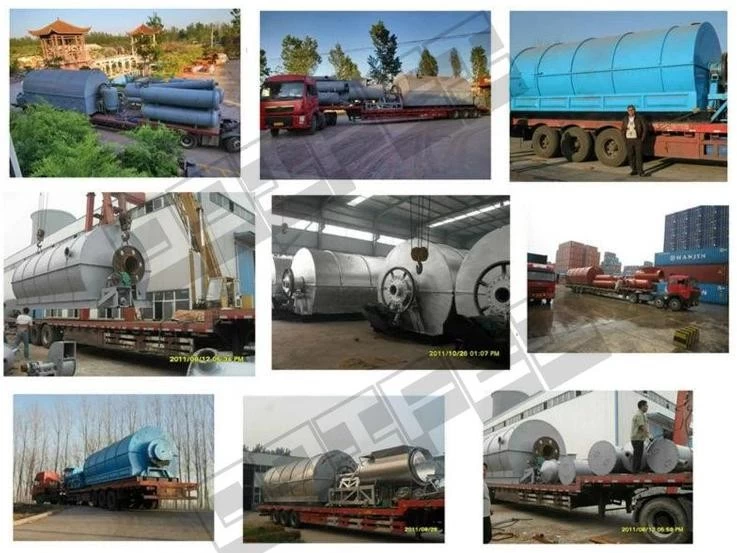

Success case