- Browse Categories

- Continuous waste tire pyrolysis equipment

- Continuous waste rubber pyrolysis equipment

- Continuous waste plastic pyrolysis equipment

- batch type waste tyre/plastic pyrolysis machine

- Waste engine oil refining equipment

- Waste Gear Oil Recycling Machine

- Used Fuel Oil Purification Machine

- Pyrolysis oil refining machine

- Garbage plastic to oil

- Auxiliary equipment

- Heavy oil bunner

- Subscribe

-

Get email updates on new products

- Contact Us

- Contact Now

- Hot Products

- News

-

Oil sludge

1.Sludge concept Oily sludge is one of the main pollutants in the petrochemical industry where the crude oil is mixed with the oil or other medium, and the oil can not be recovered directly and may cause pollution. 2.Brief introduction of sludge Petrochemical enterprises sewage treatment system to produce sludge mainly from the grease trap of the sediment, flotation pool scum, the remaining activated sludge, collectively referred to as "three mud." Oily sludge also includes contaminated sludge in steel smelting, sludge repayment of heavy oil in the process of repairing shipyards Oily sludge is usually composed of oil-in-water (o / w), water-in-oil (w / o) and suspended solids consisting of a stable suspension of emulsion system, poor dehydraDelivery to Russia

This is tons waste tyre pyrolysis equipmentCustomer equipment display

Customer equipment display6 tons waste tire pyrolysis plant

6 tons waste tire pyrolysis plant This is 6 tons waste tire pyrolysis plant . We shiped to Kazakhstan by train.customer factory show

This is the customer's spot map. His handling capacity is 10 tons per day, the raw material is waste tire. The finished products are fuel oil, steel wire and carbon black.Deliver goods

Customer factory

This is our customer factory. This plant is 10 tons capacity per day.It can pyrolysis waste tire,waste plastic and waste rubber.Safety, environmental protection, pollution-free.How to choose a suitbale factory to product the waste tyres recycling machine?

How to choose a suitbale factory to product the waste tyres recycling machine? More and more people are optimistic about the project of refining equip...50 tons heavy fuel oil distillation equipment instillation

50 tons heavy fuel oil distillation equipment instillationAutomatic slagging screw

This is a fully automatic carbon black slag discharge system. Can achieve no pollution, no dust.

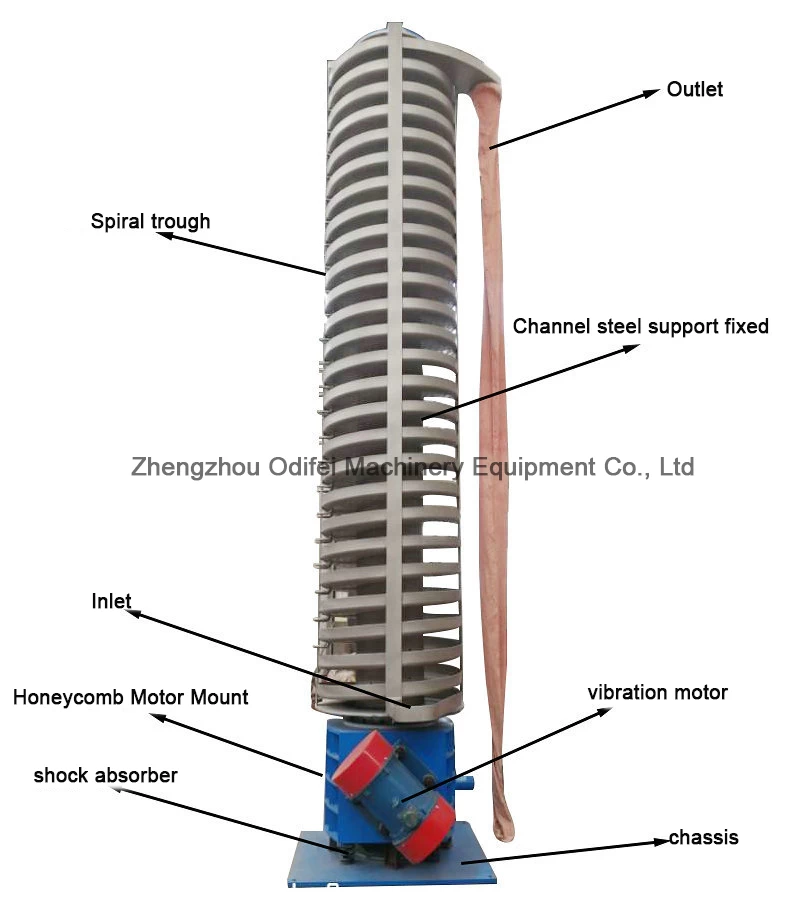

Heat Dissipation Vertical Vibration Elevator

- Conveyor trough diameter:300-900mm

- Height:≤8m

- Conveying capacity:4ton/hour,Customized

- Power: 2*(0.4-3)kw

- Frame material: SUS304/Carbon Steel

- Speed:Customized

- Customization: up-vibration, down-vibration, air-cooled, water-cooled, closed, open, 360-degree feeding, etc.

- Application: For conveying Conveying all kinds of powdery materials

- Warranty:One year.

- Color:Customized

- Voltage:380V/50HZ

- Brand Name:ODF

Working Principle Of Heat Dissipation Vertical Vibration Elevator

Heat Dissipation Vertical Vibration Elevator is composed of lifting slot, vibration motor, damping system and base. This series of hoists uses the vibration motor as the vibration source. The center lines of two vibration motors of the same model fixed on the lifting groove are installed at a certain angle and rotate synchronously in the opposite direction. The component of the centrifugal force generated by the eccentric block of the vibration motor at each instantaneous position during rotation moves back and forth along the throwing direction, so that the whole body supported on the shock absorber vibrates continuously, Make the material move upward while being thrown up in the lifting groove. After the material falls into the feeding groove, it begins to be thrown up. At this time, the material can be in full contact with the air and play the role of heat dissipation and cooling. The elevator can transport powder, block and short fiber solid materials (except those with viscosity and easy caking) vertically, and can also complete the drying and cooling of materials.

Features

1. The product occupies a small area, which is convenient for process layout.

2. Materials can be conveyed upwards or downwards.

3. Low noise, simple structure, convenient installation and maintenance.

4. The structure is simple and reasonable, the energy consumption is small, the electric energy is saved, and the wear and tear of the trough is small.

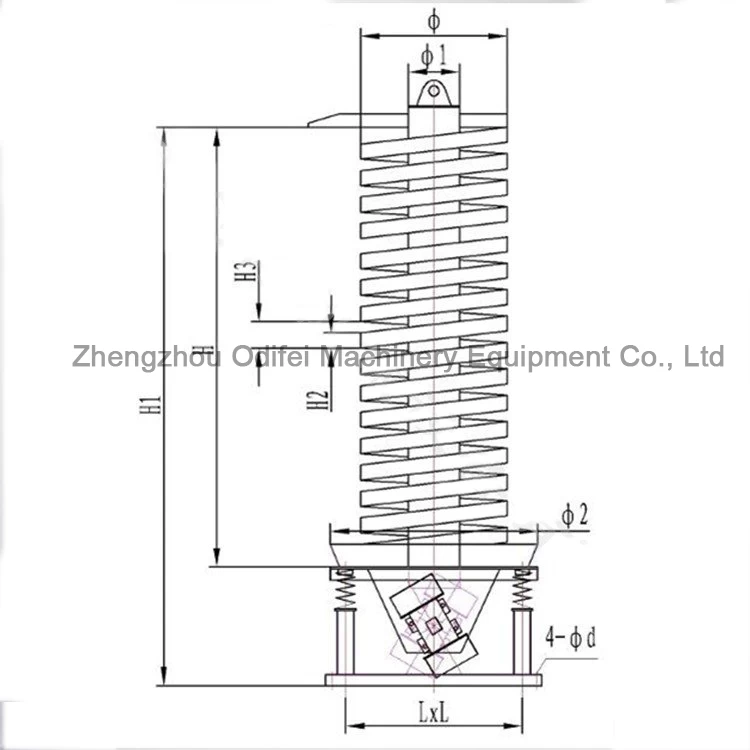

Structure Diagram

The motor vibration vertical hoist is composed of a lifting tank, a vibration motor, a vibration reduction system and a base.

Technical Parameter

| Model | Conveying Capacity(T/H) | Trough Diameter (Mm) | Conveying Width(Mm) | Conveying Height (M) |

Vibration Times (Min) | Double Amplitude(Mm) | Motor Power (Kw) | Weight(Kg) |

| DZC300 | ~1.0 | 3-8 | 77 | ≤2.2 | 960 | 6~7 | 2x0.4 | 680 |

| DZC500 | ~2.0 | 6-15 | 140 | ≤3.0 | 6~8 | 2x0.75 | 1010 | |

| DZC550 | ~3.0 | 10-25 | 152 | ≤3.5 | 6~8 | 2x1.5 | 1190 | |

| DZC600 | ~3.0 | 25-35 | 163 |

≤4.0 | 6~7 | 2x1.5 | 1321 | |

| DZC800 | ~4.0 | 19-40 |

224 | ≤4.5 | 6~8 | 2x2.2 | 1590 | |

| DZC850 | ~4.0 | 35-50 |

224 | ≤5.0 | 6~9 | 2x2.2 | 1750 | |

| DZC900 | ~3.5 | 42-60 |

185 | ≤6.0 | 6~9 | 2x3.0 | 2100 |

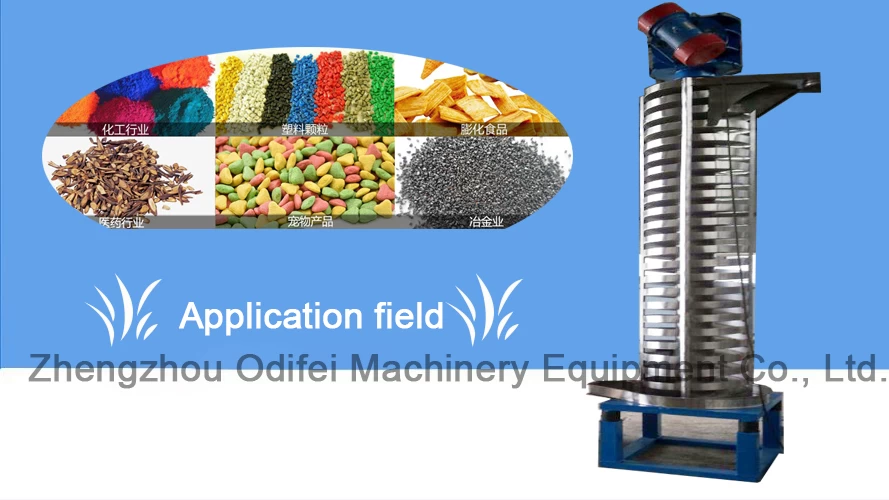

Application Range

1.Chemical Industry: resin, paint, medicine, medicine, cosmetics, fire extinguishing agent, plastic powder, abrasive glass, etc.

2.Ceramic Industry: abrasives, alumina, porcelain mud, clay mud, glass powder, refractory materials, quartz sand, PVC resin Powder, citric acid, polyethylene powder, washing powder, etc.

3.Food Industry: sugar, monosodium glutamate powder, salt, fruit juice, starch, milk powder, food, soy milk, egg powder, rice noodles, soy sauce, fish Powder, pineapple juice, etc.

4.Metallurgical Industry: carbon black, cosolvents, activated carbon, pearls, etc.

Type

Ordinary cooling type: lifting cooling, height can be customized, natural cooling;

360-degree feeding type: multi-angle feeding, meeting the needs of production operations, saving time and effort

Fan cooling type: Super temperature-controllable cooling system, which can quickly cool and dry materials while conveying;

Acrylic cover type: transparent sealing cover, no dust, can observe the operation of materials;

Our Guarantees And Services

Pre-Sale Service:

Guide customers to choose the appropriate equipment model.

Send engineering and technical personnel to the production site in time to plan the site for customers, design reasonable processes and solutions.

We can design and manufacture products according to the special needs of customers to meet the different needs of investors

On Sale Service:

Strict inspection of products before leaving the factory

Ships according to contract

After-Sale Service:

The main warranty period of the equipment sold by our company is one year (except for the failure or damage caused by human factors, fuel factors or irresistible natural phenomena, and vulnerable parts are not covered by the warranty: fuel injectors, pump heads, photosensitive eyes, etc.).

If the equipment failure is caused by human factors, the cost will be charged according to the factory price.

After receiving the warranty notice, reply within 2 hours. 24 hours technical guidance to solve problems.

A: We are a factory, established in 2007, specializing in the manufacture of vertical vibration hoists, vertical vibration elevator, bucket elevators, belt conveyors, scale conveyors, screw conveyors, etc. This vertical vibrating hoist can cool down the material while lifting.

Q: How About Spare Parts?

A: We always provide spare parts at cost price and give you a list of spare parts when you buy the machine.

Q: Will You Test The Heat Dissipation Vertical Vibration Hoist Before Delivery?

A: Yes, we will test each machine and production line before delivery, and send the working video to you. You can also check with us before delivery.

Q: What Is The Reason If The Material Does Not Go Up During The Debugging Process?

A: Check whether the screw of the motor eccentric block is loose

Q: What Is The Reason For The Overflow Phenomenon?

A: Check whether the feeding is uniform or whether there is a phenomenon of jamming.

Q: What Is The Reason For The Failure To Produce Output?

A: It is necessary to adjust the included angle of the eccentric block of the motor.

Q: What Is The Reason For The Abnormal Sound?

A: Check the wear degree of the rubber spring.