How To Refine Waste Tires?

How To Refine Waste Tires?

Process flow of waste tire refining equipment:

① The tires are loaded through the company's independently developed hydraulic automatic feeder. The loading time is shortened by 2 hours compared with manual feeding, which improves work efficiency;

② After charging is completed, close the furnace door and use the heavy oil burner independently developed by our company to heat the main cracking furnace so that the entire thermal cracking process can be carried out in a closed environment;

③ When the temperature reaches 160℃, oil and gas will begin to be generated;

④ Oil and gas enter the oil and gas purification system through the air outlet, and the oil and gas are purified to prevent the subsequent cooling pipe from being blocked;

⑤ The box cooling system cools the oil and gas, and the oil and gas are condensed into cracked oil and stored in the oil tank;

⑥ The non-condensable gas passes through the safety water seal (also called a flame arrester, its function is to prevent the open flame from returning from the combustion chamber to meet the exhaust gas and burn), and enters the combustion chamber as fuel to heat the cracking furnace; the excess non-condensable gas enters other furnaces for processing Heating, saving fuel.

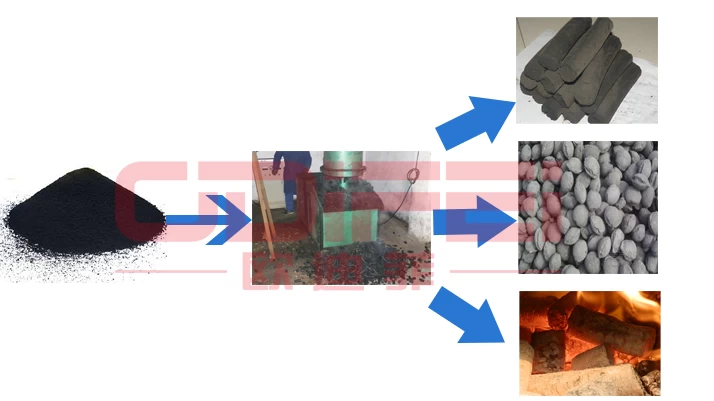

⑦ The rear end of the cracking furnace is equipped with a gas outlet and a slag outlet. After the oil and gas are discharged, the temperature of the main cracking furnace will drop. At the same time, the carbon black produced by cracking will directly fall into the scraper conveyor and be transported to the cold bucket conveyor. The elevator transports the carbon black into the storage bin and uses an automatic baling machine for automatic packaging.

⑧ The smoke and dust generated by combustion are purified through the spray dust removal system to meet emission standards;

⑨When the temperature of the cracking reactor drops to 50 degrees, turn off the power, and workers can open the furnace door and use the grab truck to pull out the steel wire in the reactor;

The waste tire refining equipment is environmentally friendly and pollution-free during the entire refining process. The waste tire refining process is simple to operate. After purchasing Odifi's waste tire refining equipment, our engineers will provide installation and guidance to solve your worries.

If you are interested in this machine,please contact us with below:

Email:doris@odifei.com.cn

Whatsapp/Mob:+86-13303710540