- Parcourir les catégories

- Équipement continu de pyrolyse de pneu de rebut

- Équipement de pyrolyse en caoutchouc pour déchets

- Matériel de pyrolyse en plastique à déchets

- Machine de pyrolyse de pneu / plastique à déchets

- ÉquipeÉquipement de raffinage du pétrole à moteur

- Machine à recycler les huiles usagées

- Machine de purification d'huile de carburant

- Machine de raffinage d'huile de pyrolyse

- Déchets plastiques à l'huile

- Équipement auxiliaire

- Heavy oil bunner

- S\'abonner

-

Recevez des mises à jour par e-mail sur les nouveaux produits

- Nous contacter

- Contacter maintenant

- Produits chauds

-

Boue de pétrole

1.Sludge concept La boue huileuse est l'un des principaux polluants dans l'industrie pétrochimique où le pétrole brut est mélangé à de l'huile ou à un autre milieu, et l'huile ne peut être récupérée directement et peut provoquer une pollution. 2. Brève introduction de boues Le système de traitement des eaux usées des entreprises pétrochimiques produit des boues principalement à partir du piège à graisse des sédiments, de l'écume de la piscine de flottation, des boues activées restantes, collectivement appelées «trois boues». Les boues grasses incluent également des boues contaminées dans la fonte d'acier, le remboursement des boues d'huile lourde dans la réparation des chantiers navals Les boues huileuses sont habituellement composées d'huilLivraison en Russie

C'est un équipement de pyrolyse de pneus usés de 6 tonnes Affichage de l'équipement client

Affichage de l'équipement client6 tonnes usine de pyrolyse des pneus usagés

6 tonnes usine de pyrolyse des pneus usagés C'est usine de pyrolyse de pneu de rebut de 6 tonnes. Nous avons expédié au Kazakhstan en train.Livrer des marchandises

Usine client

C'est notre usine de clients. Cette plante a une capacité de 10 tonnes par jour. Elle peut pyrolyser les pneus usés, les déchets de plastique et les déchets de caoutchouc. Sécurité, protection de l'environnement, sans pollution.usine de client

C'est la carte du client. Sa capacité de traitement est de 10 tonnes par jour, la matière première est un pneu usé. Les produits finis sont le mazout, le fil d'acier et le noir de carbone.Scellage automatique

Ceci est un système de décharge de scories noir de carbone entièrement automatique. Peut atteindre aucune pollution, aucune poussière.Comment choisir une usine de gardiens pour produire la machine de recyclage des pneus de pneus?

Comment choisir une usine de gardiens pour produire la machine de recyclage des pneus de pneus? De plus en plus de personnes sont optimistes quant au ...Qu'est-ce que la machine de pyrolyse?

Qu'est-ce que la machine de pyrolyse? Le Pyrolyse est un équipement de recyclage des déchets conçu pour convertir les pneus de déchets, les plasti...

Fully continuous waste rubber pyrolysis oil machine

- Condition:New

- Type:Other

- Place of Origin:Henan, China (Mainland)

- Brand Name:ODF

- Voltage:Customer Request

- Power(W):55KW

- Dimension(L*W*H):30m*18m*5m

- Weight:60T

- Certification:CE ISO SGS

- Warranty:1 Year

- After-sales Service Provided:Engineers available to service machinery overseas

- Name:Tyre Oil Extraction Plant

- Raw material:Waste Tyre

- Application:Continuous Tyre Pyrolysis Plant

- Function:Make Oil

- End product:Fuel Oil Steel Carbon Back

- Color:Customers' Demand

- Item:Oil Equipment

- Suitable Raw Materials:Scrap Steel Tire

Fully continuous waste rubber pyrolysis oil machine

Latest continuous feeding system in the pyrolysis process does not require a restart or stop, so it has more processing capacity.Compared with intermittent feeding system, powerful automation has the great advantage of the continuity system, reduced downtime and labor costs, improve work efficiency.

Material

Solid: waste tyre, waste rubber product, waste plastic

Material

Solid: waste tyre, waste rubber product, waste plastic

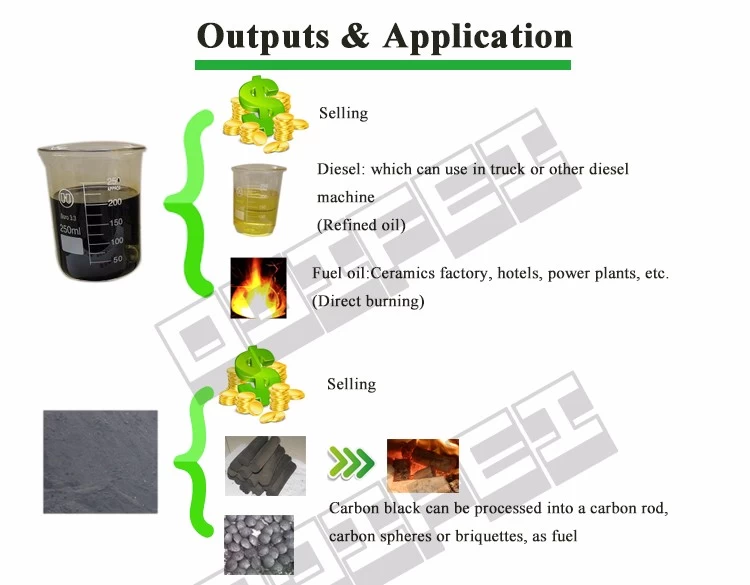

Output for waste tires:

45%-50% fuel oil

30%-35% carbon black

10%-12% steel wire

8%-10% waste gas

45%-50% fuel oil

30%-35% carbon black

10%-12% steel wire

8%-10% waste gas

Continuous thermal machines from the feed,slag, residue oil-water separation and transport respectively, all are automatic, mechanical control. The whole operation is controlled by a PLC operating system our unique design, managed 20/30 ton device needs only two workers

Save Energy

Throughout the production process only when the machine is started you need start 30 kilograms of fuel, once the machine starts running, its own generate enough gas to supply the normal operation of the machine.under the case of electricity at a reasonable cost, the system can last for several months

Low emissions

Unique three-in-one system includes desulphurization and dust removal, water film dust and spray dust three sets of systems, through these three systems to absorb emissions of carbon dioxide and dust to make it meet the State discharge standards

Easy to maintain

Continuous pyrolysis system is easy to operate and easy to maintain. Under the catalytic role of the special design, the entire system can last 6 months

Long servicelife

The system uses hot air as a medium to deliver heat evenly to the reactor. Because the reactor is not directly heated, and maintains the temperature inside the oven at 400 degrees, so that the equipment service life of up to 15 years

Save Energy

Throughout the production process only when the machine is started you need start 30 kilograms of fuel, once the machine starts running, its own generate enough gas to supply the normal operation of the machine.under the case of electricity at a reasonable cost, the system can last for several months

Low emissions

Unique three-in-one system includes desulphurization and dust removal, water film dust and spray dust three sets of systems, through these three systems to absorb emissions of carbon dioxide and dust to make it meet the State discharge standards

Easy to maintain

Continuous pyrolysis system is easy to operate and easy to maintain. Under the catalytic role of the special design, the entire system can last 6 months

Long servicelife

The system uses hot air as a medium to deliver heat evenly to the reactor. Because the reactor is not directly heated, and maintains the temperature inside the oven at 400 degrees, so that the equipment service life of up to 15 years