- Examinar las categorías

- Equipo continuo de la pirolisis del neumático

- Equipo de pirólisis de caucho residual continuo

- Continuous waste plastic pyrolysis equipment

- batch type waste tyre/plastic pyrolysis machine

- Equipo de refinación de aceite de motor inútil

- Máquina de reciclaje de aceite de engranaje de res

- Máquina usada de la purificación del aceite de

- Máquina de refinado de petróleo Pyrolysis

- Basura plástica a aceite

- Equipo auxiliar

- Heavy oil bunner

- Suscribir

-

Reciba actualizaciones por correo electrónico sobre nuevos productos

- Contáctenos

- Contacta ahora

- Productos

-

Lodo de aceite

1.Sludge concepto El lodo aceitoso es uno de los principales contaminantes de la industria petroquímica, donde el crudo se mezcla con el aceite u otro medio, y el aceite no puede ser recuperado directamente y puede causar contaminación. 2.Brief introducción de lodos Las empresas petroquímicas sistema de tratamiento de aguas residuales para producir los lodos, principalmente de la trampa de grasa del sedimento, la escoria de la piscina de flotación, el resto de los lodos activados, denominados colectivamente "tres barro". Los lodos aceitosos también incluyen lodos contaminados en fundición de acero, devolución de lodos de petróleo pesado en el proceso de reparación de astilleros El lodo aceitoso se compone generalmente de aceite en agua (o /Entrega a Rusia

Esto es 6 toneladas de equipos de pirólisis de neumáticos de desecho Exhibición del equipo del cliente

Exhibición del equipo del clientePlanta de pirólisis de neumáticos de desecho de 6 toneladas

Planta de pirólisis de neumáticos de desecho de 6 toneladas Esta es una planta de pirólisis para neumáticos de desecho de 6 toneladas. Fuimos a Ka...Entregar bienes

Fábrica de clientes

Esta es nuestra fábrica de clientes. Esta planta es de 10 toneladas de capacidad por day.It puede pirólisis residuos de neumáticos, residuos de plástico y residuos de caucho. Seguridad, protección del medio ambiente, libre de contaminación.fábrica del cliente

Este es el mapa de puntos del cliente. Su capacidad de manejo es de 10 toneladas por día, la materia prima es llanta de desecho. Los productos terminados son aceite combustible, alambre de acero y negro de humo.Tornillo de escoria automática

Este es un sistema de descarga de escoria de negro de humo completamente automático. No puede lograr contaminación, no hay polvo.¿Cómo elegir una fábrica de Suitbale para producir la máquina de reciclaje de neumáticos para desech

¿Cómo elegir una fábrica de Suitbale para producir la máquina de reciclaje de neumáticos para desechos? Cada vez más personas son optimistas sob...¿Qué es la máquina de pirólisis?

¿Qué es la máquina de pirólisis? El Máquina de pirólisis es un equipo de reciclaje de materiales de desecho diseñado para convertir neumáticos...

China fully continuous waste plastic pyrolysis oil equipment manufatcture

- Condition:New

- Type:Other

- Place of Origin:Henan, China (Mainland)

- Brand Name:ODF

- Voltage:Customer Request

- Power(W):55KW

- Dimension(L*W*H):30m*18m*5m

- Weight:60T

- Certification:CE ISO SGS

- Warranty:1 Year

- After-sales Service Provided:Engineers available to service machinery overseas

- Name:Tyre Oil Extraction Plant

- Raw material:Waste Tyre

- Application:Continuous Tyre Pyrolysis Plant

- Function:Make Oil

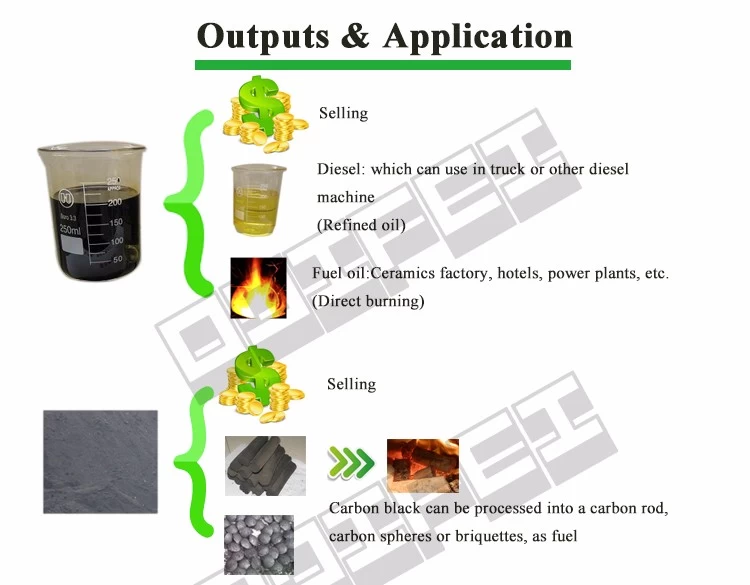

- End product:Fuel Oil Steel Carbon Back

- Color:Customers' Demand

- Item:Oil Equipment

- Suitable Raw Materials:Scrap Steel Tire

China fully continuous waste plastic pyrolysis oil equipment manufatcture

Latest continuous feeding system in the pyrolysis process does not require a restart or stop, so it has more processing capacity.Compared with intermittent feeding system, powerful automation has the great advantage of the continuity system, reduced downtime and labor costs, improve work efficiency.

Material

Solid: waste tyre, waste rubber product, waste plastic

Material

Solid: waste tyre, waste rubber product, waste plastic

Output for waste tires:

45%-50% fuel oil

30%-35% carbon black

10%-12% steel wire

8%-10% waste gas

45%-50% fuel oil

30%-35% carbon black

10%-12% steel wire

8%-10% waste gas

Continuous thermal machines from the feed,slag, residue oil-water separation and transport respectively, all are automatic, mechanical control. The whole operation is controlled by a PLC operating system our unique design, managed 20/30 ton device needs only two workers

Save Energy

Throughout the production process only when the machine is started you need start 30 kilograms of fuel, once the machine starts running, its own generate enough gas to supply the normal operation of the machine.under the case of electricity at a reasonable cost, the system can last for several months

Low emissions

Unique three-in-one system includes desulphurization and dust removal, water film dust and spray dust three sets of systems, through these three systems to absorb emissions of carbon dioxide and dust to make it meet the State discharge standards

Easy to maintain

Continuous pyrolysis system is easy to operate and easy to maintain. Under the catalytic role of the special design, the entire system can last 6 months

Long servicelife

The system uses hot air as a medium to deliver heat evenly to the reactor. Because the reactor is not directly heated, and maintains the temperature inside the oven at 400 degrees, so that the equipment service life of up to 15 years